- Support the training in mechanical engineering design

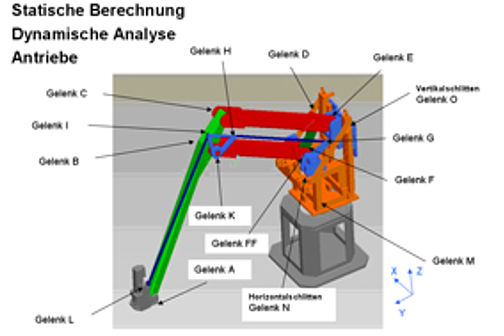

- Application of CAD and FEM in the CAE process

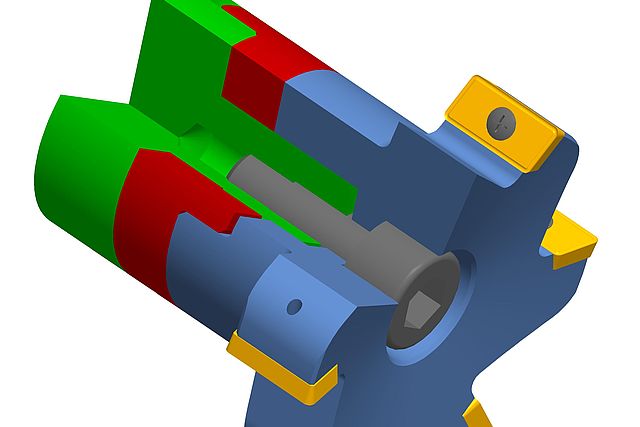

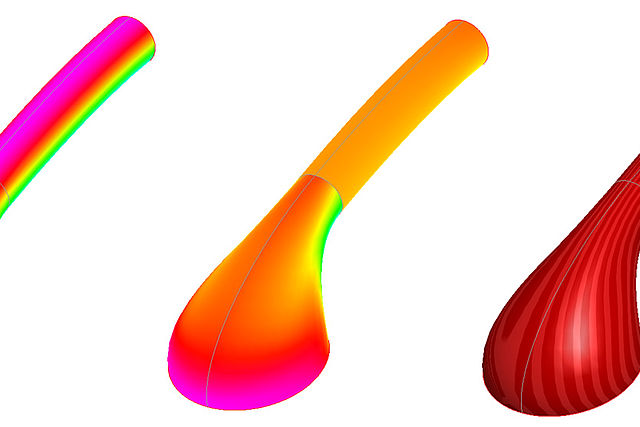

- Design studies with 3D CAD

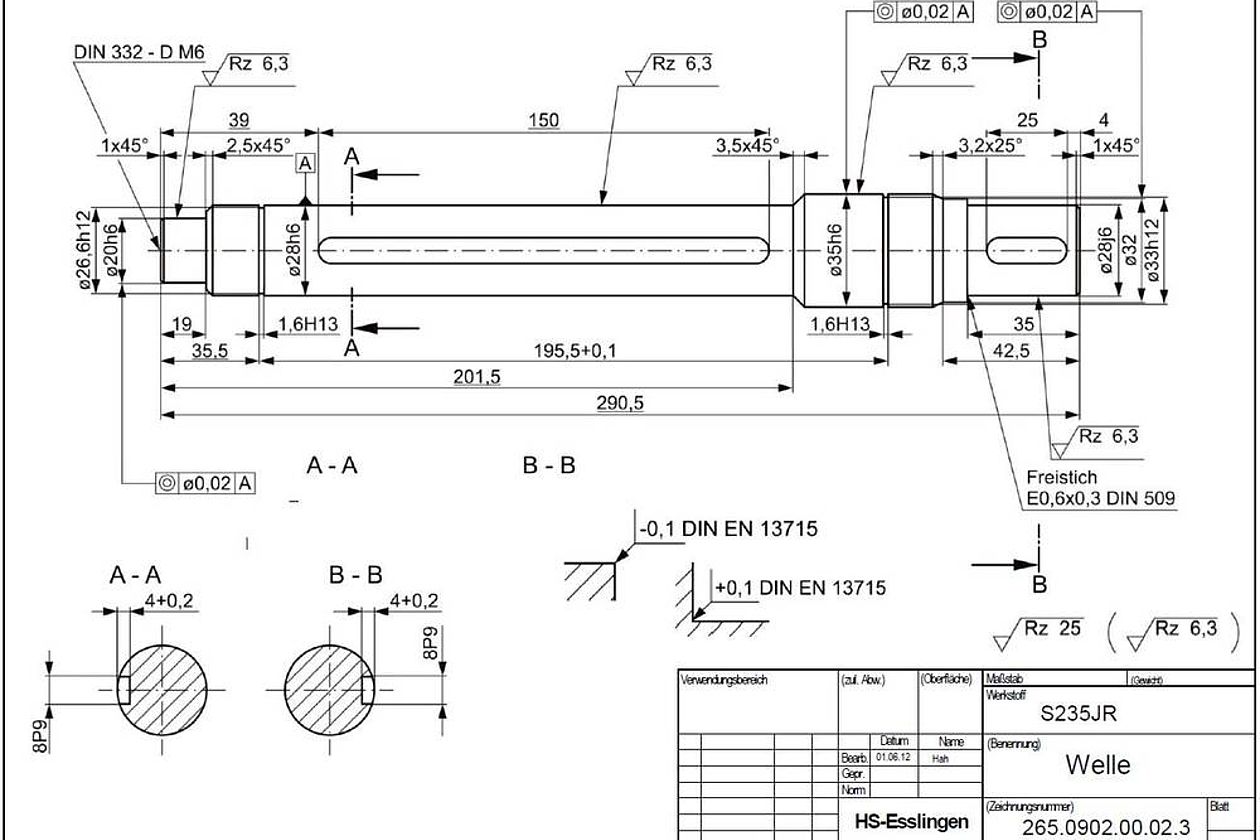

- Computer-aided dimensioning of machine parts

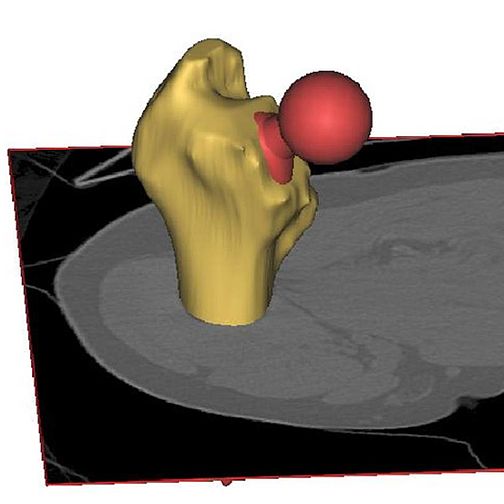

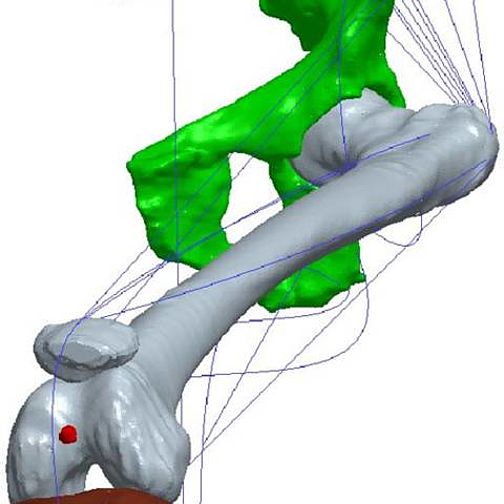

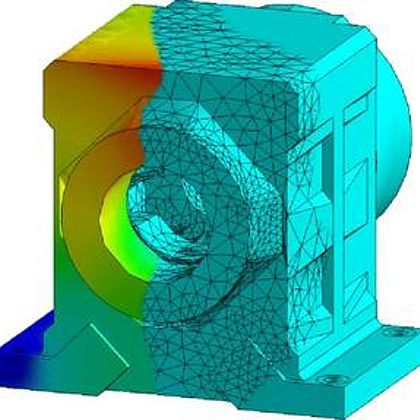

- Finite Element analyses for the simulation of the component behaviour under mechanical and thermal loads

- Dimensioning of components in relation to fatigue strength

- Numerical simulation and visualisation of dynamic processes

- Represent Esslingen University of Applied Sciences in working groups for design and CAD at the Baden-Württemberg universities of applied sciences.

![Total deformation of the model (scaled 30x) [Source: ANSYS Workbench]](/fileadmin/_processed_/b/f/csm_Gesamtverformung_des_Modells__30x_skaliert__7d79d27b62.jpg)

![Equivalent stress in the lower notch radius [source: Ansys Workbench]](/fileadmin/_processed_/6/7/csm_Vergleichsspannung_9f4c149dfd.jpg)